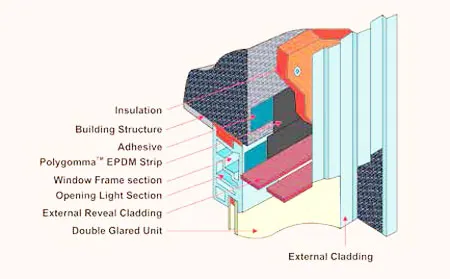

Polygomma EPDM Strips are durable sealing materials made from cross-linked EPDM rubber. They protect construction joints and building envelopes from water, air, and environmental damage. Commonly used to seal façades, window perimeters, and as a Damp Proof Course (DPC) in foundations and walls.

- Sealing joints between façades, windows, and structural elements

- Acting as Damp-Proof Course in masonry and concrete

- Flexible seals for expansion joints

- Vapour and moisture barrier in residential and commercial buildings

| Property | Details |

| Material | EPDM (Ethylene Propylene Diene Monomer) |

| Thickness Range | 0.8 mm to 2.0 mm (single ply) |

| Widths Available | Pre-cut from 0.05 meters onwards |

| Elongation at Break | > 300% |

| Service Temperature Range | –40°C to +150°C |

| µ Value (Water Vapour Resistance) | 54,000 (ASTM E96-16) |

| Fire Retardant Grade | Available upon request |

| Installation Method | Adhesive bonding or mechanical fixing |

Polygomma EPDM Strips are supplied in rolls or pre-cut sections for ease of handling on-site. Surfaces should be clean and dry before application. Depending on the substrate and project type, the strips can be affixed using adhesives or mechanically fastened.

The product is tested according to industry standards, including ASTM E96-16 for water vapour transmission and internal performance testing for elongation, temperature resistance, and chemical exposure durability. Fire-retardant grades undergo additional flame resistance testing.

FAQ’s

Enquire Now

As soon as you contact our expert team, this will be the only form you have to fill in!